.png)

.png)

.png)

-

.png) 0086-757-85407388

0086-757-85407388 -

-

terrychen@wintoly.com

terrychen@wintoly.com

.png)

.png)

.png)

.png)

In the world of surface finishing, one technology is making waves - sublimation powder coating. These innovative methods provide superior durability, aesthetic appeal, and environmental sustainability compared to traditional finishing techniques. In this article, we'll delve into the intricate details of these processes, comparing them with conventional methods, and exploring their myriad applications. Buckle up for an enlightening journey into the future of surface finishing.

Powder coating is a highly efficient and environmentally friendly surface finishing method that has gained considerable popularity in various industries. This dry finishing process involves the application of a fine, dry powder to a surface, which is then heated (or cured) to form a hard, protective layer. Unlike traditional liquid paint, powder coating doesn't require a solvent, making it a more sustainable choice.

One of the significant advantages of powder coating is its wide range of applications. It can be used on metals, plastics, and even some wood products, making it highly versatile. Additionally, it offers an excellent finish that is resistant to scratching, chipping, and other forms of wear and tear.

In the context of our discussion, we will be focusing on a unique type of powder coating known as heat transfer powder coating. This innovative method combines the durability of powder coating with the ability to create intricate designs, promising a future where aesthetics and durability go hand in hand.

Sublimation powder coating, also known as heat transfer powder coating, is a revolutionary technique in the world of surface finishing. This process incorporates the principles of sublimation, where a substance transitions from a solid to a gas without going through a liquid phase, to achieve unique and highly detailed designs on a coated surface.

The process starts with the application of a base powder coating to the material. This creates a solid, durable layer that serves as the canvas for the sublimation process. A pre-printed transfer film, carrying the desired design, is then wrapped around the coated object. When subjected to high heat, the inks on the film sublimate and permeate the powder coating, resulting in a vibrant, long-lasting design.

Sublimation powder coating not only offers a higher degree of design flexibility compared to traditional powder coating but also retains all the advantages of the latter. It's durable, eco-friendly, and versatile, making it a top choice for businesses that prioritize quality and aesthetics in their products.

The term 'sublimation' in 'sublimation powder coating' isn't just a fancy name—it refers to the actual physical and chemical process that takes place during heat transfer powder coating. But what exactly is sublimation?

Sublimation is a fascinating phenomenon in physics and chemistry where a substance transitions directly from the solid phase to the gas phase without passing through the intermediate liquid phase. This process occurs under specific conditions of temperature and pressure.

In the context of sublimation powder coating, the inks used on the transfer film are made from special dyes that can sublimate. When heated, these dyes turn into gas and permeate through the powder coating. As the object cools, the gaseous dyes condense back into solid form, becoming a part of the coated surface. This results in the vibrant and durable design characteristic of sublimation powder coating.

This process is a remarkable fusion of physics and chemistry, playing a significant role in the world of surface finishing. It's what allows us to create such vibrant, long-lasting, and highly detailed designs on coated objects.

The materials used in powder coating play a crucial role in determining its properties, application, and effectiveness. Generally, there are two main types of materials used: thermosets and thermoplastics.

Thermosetting powders are widely used in powder coating processes. When heated, these materials undergo a chemical reaction that forms a three-dimensional network, creating a hard, durable finish. Unlike thermoplastics, this process is irreversible, meaning the material cannot be remelted or reshaped once cured. This characteristic makes thermosets particularly suitable for applications that require high resistance to heat, chemicals, and electrical insulation.

On the other hand, thermoplastics are materials that can be melted, cooled, and remelted without significant degradation. Unlike thermosets, they do not undergo any chemical change during the heating process. This characteristic makes them useful for applications where recyclability and reshaping are desired. However, thermoplastics generally have lower chemical and heat resistance compared to thermosets.

The process of sublimation powder coating, although intricate, can be broken down into several key steps. Each step plays a crucial role in achieving the final product's desired finish and durability.

The first step in the process involves preparing the surface of the object to be coated. This typically includes cleaning to remove any dirt, oil, or rust and can also involve abrading the surface to improve the adhesion of the coating.

The object is then coated with a layer of powder. This is typically done using a spray gun, which applies a positive electric charge to the powder particles, causing them to adhere to the grounded object. The object is then heated in a curing oven, causing the powder to melt and form a smooth, solid coating.

Next, a transfer film printed with the desired design is wrapped around the coated object. This film is designed to withstand the high heat of the sublimation process without distorting the printed design.

The object is then heated again. The heat causes the dyes on the transfer film to sublimate, or turn into a gas, and permeate the powder coating. Once the heating process is completed, the transfer film is removed, revealing a vibrant, durable, and highly detailed design on the surface of the object.

While the process of sublimation powder coating requires specialized equipment and expertise, the fundamental steps can be broken down into a straightforward guide. Whether you're an industry professional looking for a refresher or a curious enthusiast, here's a step-by-step look at the process:

Every good coating job starts with thorough surface preparation. The object to be coated should be free of dirt, oil, rust, or any other contaminants. Techniques such as sandblasting, chemical cleaning, or ultrasonic cleaning might be used depending on the material and the degree of contamination.

The clean object is then coated with a layer of powder. The powder is usually applied with an electrostatic spray gun, which imparts a positive charge to the powder, causing it to adhere to the grounded object. The coated object is then placed in an oven where the powder melts and forms a smooth, continuous film.

Once the base coat has cooled, a pre-printed transfer film carrying the desired design is wrapped around the object. The film should be applied tightly to ensure the design transfers accurately to the object's surface.

The object is then reheated. During this stage, the inks on the transfer film sublimate, or transition directly from a solid to a gas, and permeate the base coat. This step may take some time and should be performed in a controlled environment to ensure the best results.

Once the sublimation process is complete, the object is allowed to cool. The transfer film is then removed, revealing a vibrant, permanent, and high-resolution design. The coated object is now ready for use or further processing, as required.

The sublimation powder coating process necessitates the use of several specialized pieces of equipment. Each component plays a unique role in ensuring the process runs smoothly and efficiently. Here's an overview of the main types of equipment used:

Before any coating can occur, the surface of the object to be coated must be impeccably clean. Various cleaning equipment such as sandblasters, ultrasonic cleaners, or chemical baths might be used depending on the specifics of the project.

The powder coating itself is typically applied using an electrostatic spray gun, which imparts a positive charge to the powder, causing it to adhere to the grounded object. This equipment includes the powder feed system, the electrostatic sprayer, and a recovery system for oversprayed powder.

Once the object is coated with powder, it is placed in a curing oven. This oven is designed to heat the object evenly to a specified temperature, causing the powder to melt into a continuous, smooth film.

The transfer film, pre-printed with the desired design, is applied to the coated object using a heat press. The heat press applies both heat and pressure to the transfer film, triggering the sublimation process.

Each of these pieces of equipment plays a crucial role in the sublimation powder coating process, contributing to the high-quality, durable, and attractive finishes that this method can achieve.

As with any industrial process, safety should be the number one priority when performing sublimation powder coating. This process involves handling various chemicals, equipment, and heat sources, each of which has associated risks. Here are the key safety measures to consider:

Workers should always wear appropriate PPE, including protective clothing, gloves, safety glasses, and respiratory protection, especially when handling powder coating materials and operating equipment.

Proper ventilation is crucial in any area where powder coating is being applied or cured to minimize the risk of inhalation of powder particles or fumes.

As curing ovens are used in the process, there's a risk of fire. Therefore, fire safety measures, such as keeping flammable materials away from the heat source, regular equipment checks, and fire extinguishers on site, should be in place.

All workers should be properly trained on the safe use of all equipment, including cleaning tools, spray guns, and ovens. Regular equipment maintenance and inspection are also essential to prevent accidents.

Sublimation powder coating is a versatile process that finds its application in various industries due to its durability, aesthetics, and environmental friendliness. Here are some of the key applications:

In the architecture and construction industry, sublimation powder coating is used for coating window frames, railings, and other architectural components. It offers a wide range of colors and textures, and is resistant to weathering and corrosion.

In the automotive industry, sublimation powder coating is used for coating car parts, such as wheels, grills, bumpers, and other accessories. It provides a high-quality finish that is resistant to chipping, scratching, and fading.

In the furniture industry, sublimation powder coating is used for coating metal furniture, such as chairs, tables, and cabinets. It provides a smooth, attractive finish that is easy to clean and maintain.

Sublimation powder coating is also used in the sports industry for coating equipment like bicycles, golf clubs, and gym equipment. It offers a durable, corrosion-resistant finish that can withstand heavy use and exposure to the elements.

These are just a few examples of the many applications of sublimation powder coating. Its combination of durability, aesthetics, and environmental friendliness makes it a go-to choice for many industries.

Sublimation powder coating, as a technique, has been applauded for its environmental credentials. Unlike traditional liquid coatings, it is a process that does not involve solvents and therefore releases minimal volatile organic compounds (VOCs) into the atmosphere. Furthermore, any overspray or unused powder can be recovered and reused, resulting in less waste and a more efficient process. However, as with all manufacturing processes, it's important to continuously evaluate its environmental footprint and strive for improvements.

The environmental footprint of sublimation powder coating primarily lies in the energy consumed during the curing process and the production of raw materials. Regular assessments of the energy efficiency of curing ovens and the sourcing of raw materials can help in minimizing this footprint. Adopting best practices such as optimizing energy use and reducing waste is fundamental to maintaining an environmentally-friendly process.

There are several ways to enhance the sustainability of the sublimation powder coating process. One approach is investing in energy-efficient equipment that reduces power consumption. Another is to optimize the coating process to minimize waste. Also, seeking suppliers who prioritize sustainable practices for sourcing raw materials can significantly reduce the environmental footprint. By implementing these measures, businesses can contribute towards a more sustainable future while also benefiting from cost savings and efficiency improvements.

Sublimation powder coating offers several advantages that make it a preferred choice for many industries. Let's delve into these:

The sublimation process produces a highly durable and resistant coating that can withstand harsh environmental conditions, such as high temperatures and UV radiation. This ensures that the coating remains vibrant and does not chip or peel off over time.

Sublimation powder coating is more environmentally friendly than traditional liquid coatings. It does not contain harmful solvents and emits minimal volatile organic compounds (VOCs), making it a green choice for businesses.

The ability to reclaim and reuse overspray makes sublimation powder coating a cost-effective option. It also requires less maintenance than other coating methods, further reducing long-term costs.

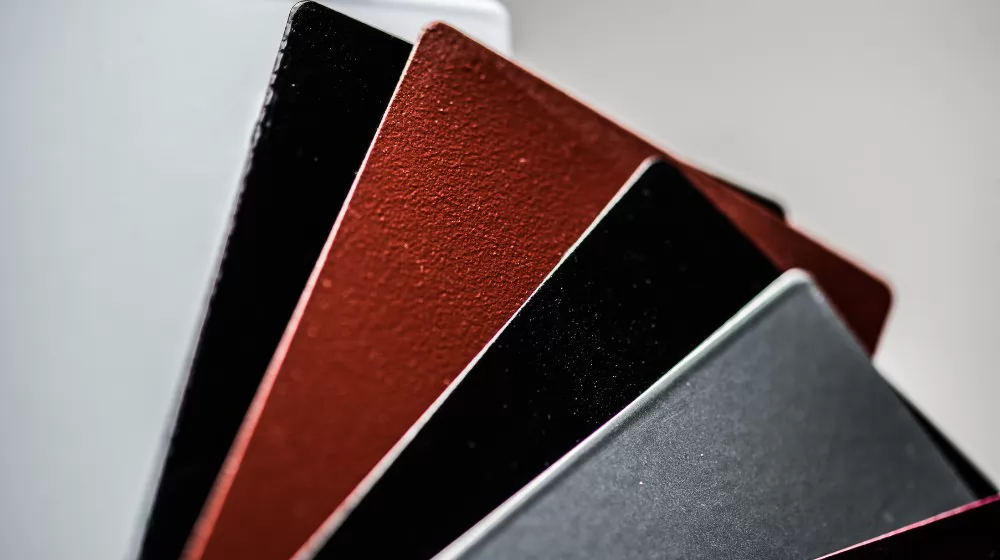

Sublimation powder coating can be used on a variety of surfaces and materials, including metals, ceramics, and plastics. It can also replicate a wide range of finishes such as wood, marble, and custom designs, making it highly versatile.

While sublimation powder coating has several advantages, it's important to consider some of its potential drawbacks. These include:

The initial setup cost for sublimation powder coating equipment can be high, making it a significant investment for small businesses. However, it's worth noting that the lower operational costs and efficiency of the process often offset this initial expense over time.

The sublimation powder coating process can be complex and requires skilled operators to ensure high-quality results. The process involves several steps, from pre-treatment to curing, each of which needs to be executed precisely.

While sublimation powder coating can be applied to a variety of materials, it does have limitations. For instance, it's typically not suitable for materials that cannot withstand the high temperatures required for the curing process.

Achieving very thin coats can be more challenging with sublimation powder coating than with some other types of coatings. This can be a limitation for specific applications where a thin, smooth finish is required.

When deciding on a coating method, it's often helpful to compare different techniques. Here's a head-to-head comparison of sublimation powder coating and liquid coating:

Sublimation powder coating offers a more durable and resistant finish compared to liquid coating. It can withstand harsh conditions and is less likely to chip or peel over time. Meanwhile, liquid coatings may provide a smoother finish, but may not be as robust.

Sublimation powder coating is more environmentally friendly than liquid coating. It doesn't contain solvents and releases fewer volatile organic compounds (VOCs). On the other hand, liquid coatings often contain solvents which can release harmful VOCs into the environment.

While the initial setup cost for sublimation powder coating can be high, the operational costs are typically lower than liquid coating. The ability to reuse overspray makes it a cost-effective option in the long run. Liquid coating, however, can be less expensive to set up, but may involve higher operating costs.

The sublimation powder coating process can be more complex and requires skilled operators. Liquid coating is a simpler process but may require multiple coats for a desired finish, extending the time and cost of the process.

When it comes to surface finishing techniques, electroplating is another common method. Let's see how sublimation powder coating compares to electroplating:

Sublimation powder coating offers a smooth and uniform finish with a wide range of colors and patterns. Electroplating, however, provides a shiny, metallic finish which may be more desirable for certain applications, but is limited in color options.

The sublimation powder coating process creates a highly durable and resistant coating, making it an excellent choice for heavy-duty applications. Electroplating, while also providing a durable finish, can be prone to tarnishing over time and may require additional protective coatings.

Sublimation powder coating is a more environmentally friendly process compared to electroplating. It does not involve harmful chemicals and produces minimal waste. Electroplating involves the use of hazardous chemicals and generates waste that must be disposed of properly, posing an environmental concern.

While sublimation powder coating requires a high initial investment, it can be more cost-effective in the long run due to its lower operating costs and the ability to reclaim overspray. Electroplating, on the other hand, can have lower upfront costs, but the ongoing costs of waste disposal and maintenance can add up.

Sublimation powder coating and heat transfer powder coating are indeed revolutionizing the coating industry. As we embrace these innovative techniques, it's essential to partner with reliable manufacturers and suppliers like Wintoly, a leading powder coating exporter in China since 2008. With over 20 years of market experience and a state-of-the-art laboratory, Wintoly provides professional coating options and solutions, ensuring high-quality and cost-effective finishes. Whether you're looking for custom coatings or specialty finishes, Wintoly's got you covered. For more information about their products and services, don't hesitate to visit their website.

Read More:

What is powder coating? Everything You Need to Know

Powder Coating vs. Paint: Unveiling the Pros and Cons

1. What is powder coating?

2. What are the benefits of using powder coating?

3. What industries commonly utilize powder coating?

4. How do I choose a reliable powder coating supplier?

5. What types of powder coatings are available?

6. What is the typical minimum order quantity (MOQ) for powder coatings?

7. Can I request custom colors or formulations?

8. How do I ensure quality control when ordering powder coatings?

9. What are the typical curing requirements for powder coatings?

10. What are the payment terms typically offered by powder coating suppliers?

11. How can I request samples of powder coatings?

12. What should I consider when applying powder coatings?

When selecting a powder coating supplier, it’s essential to evaluate their product offerings, quality assurance processes, and customer service. Doing thorough research can help you find a supplier that meets your specific needs effectively.

terrychen@wintoly.com

terrychen@wintoly.com

.png) 0086-757-85407388

0086-757-85407388

6 Chaoyang Rd., National Demonstration Eco-industrialzone, Nanhai, Foshan,Guangdong,China

6 Chaoyang Rd., National Demonstration Eco-industrialzone, Nanhai, Foshan,Guangdong,China

.png)