.png)

.png)

.png)

-

.png) 0086-757-85407388

0086-757-85407388 -

-

terrychen@wintoly.com

terrychen@wintoly.com

.png)

.png)

.png)

.png)

20 + Years of Market Experience

More than 20 years of market experience, has been a leading powder coating exporter in China since 2008

Professional Technical Support

Deeply plowing the industry for more than 20 years, providing customer-satisfied customized powder coating solutions.

Professional Manufacturer

We have advanced production equipment and our own laboratory, which can firmly control the production and product quality.

One-stop Solution

Provide customers with professional custom powder coating options and solutions with good price and high quality.

As a powder coating manufacturer, it's essential to understand that the demand for powder coating has significantly risen in recent years. With its unique properties and diverse applications, powder coating has carved a niche for itself in various industries.

The powder coating process, while seemingly straightforward, requires a good grasp of its nuances to produce a high-quality finish. This quality finish is crucial as it directly impacts the product's overall appearance, durability, and resistance to wear and tear.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike traditional liquid paint which requires a solvent for the filler and binder parts to become liquid, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

There are numerous benefits to using powder coating over traditional liquid coating. For starters, powder coatings are safe, clean, economical, and eco-friendly. They contain no volatile organic compounds (VOCs), no toxic heavy metals such as lead or chromium (VI), and they generate no paint sludge from the spray booth. Being solvent-free, powder coatings significantly reduce the risk of fire and make waste disposal easier. As they can build high film thicknesses up to 150 microns with just one coat, they offer improved productivity. Moreover, since the overspray can be reused, there's a high application efficiency of up to 99%. One of the major advantages of powder coating is its durability, which results in a low carbon footprint.

Powder coatings are a combination of the following raw materials:

Resins- Polyester or Epoxy, this gives the powder its performance capabilities. Polyester for a durable finish with good resistance to UV and weather exposure. Epoxy for good chemical resistance however not suitable for external use.

CURING AGENTS:Help to bind the coating

ADDITIVES:Various with a wide range of properties for example; degasser to help the air escape from the substrate during the curing process therefore helping to restrict pin holing.

PIGMENTS:For colour

TITANIUM DIOXIDE:White pigment used in all coatings, amongst other properties it helps to create brightness by dispersing light.

EXTENDERS:Reduce glossiness.

Once the required ingredients have been pre weighed, they are dry mixed before being extruded. This process melts the mix, activating the resin and hardeners before it is rolled flat on a conveyorised belt. The now cool mix is broken down in to chips, ground and then finely sieved to ensure no large particles contaminate the powder.

Because no solvents are present, powder coating is an environmentally friendly and cost effective alternative to traditional liquid paints. Furthermore, as the application is done electrostatically, the paint is recoverable and therefore re-usable. With no drying times required as the hardening is oven cured, powder coated products are ready to use as soon as they leave the production line!

In the realm of powder coatings, there are a variety of types available, each serving different purposes and applications. The characteristics of each type vary, making the selection of the appropriate powder coating for specific applications a crucial step. Exploring these different types helps manufacturers ensure they're choosing the right coating that would best serve the needs of their project.

Powder coating requires specialized equipment for effective application. This equipment can vary based on the specific powder application methods, which include electrostatic spray and fluidized bed, among others. The components of a typical powder coating system include a spray gun, a fluidized hopper bed, a curing oven, and a conveyor system, among others.

Proper surface preparation is a crucial step in the powder coating process. The quality of the finished product heavily depends on how well the surface was prepped before the application of the powder. It involves cleaning the surface and removing any rust, dirt, oil, or any other form of contamination. Depending on the specific needs of the project, the appropriate pretreatment method, whether chemical or mechanical, should be chosen.

During the powder coating process, certain areas may need to be protected from the coating. For such cases, masking techniques come into play. They help protect those areas that should not be coated. On the other hand, efficient hanging techniques contribute to a more efficient coating process, maximizing productivity and minimizing defects.

There are three key phases to the powder coating process:

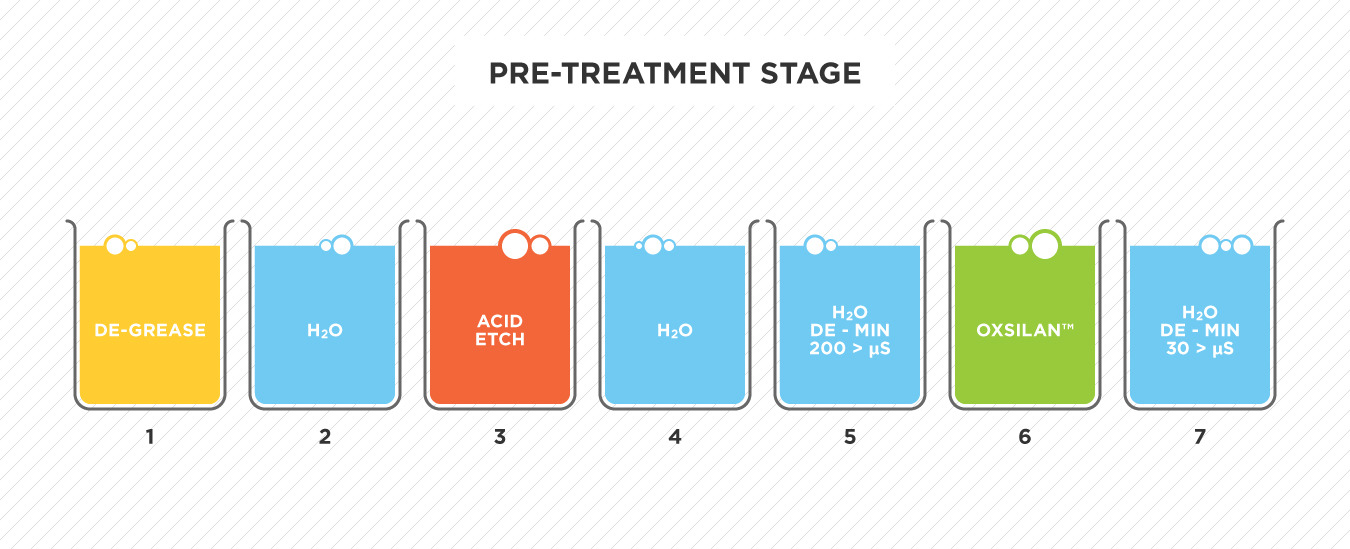

This stage is vital in allowing the paint finish to perform to its full potential. All paints are porous and will over time allow atmospheric conditions to permeate through the coating onto the metal. To safeguard against this, all substrates are chemically pre-treated in order to protect against corrosion and promote good adhesion.

The pre-treatment at Powder Coatings is a classic seven stage immersion system where work is loaded into cages before being dipped through seven tanks.

1. DE- GREASE

All metal substrates must be clean prior to any other stage. All grease or lubricant residue from the manufacturing process is removed.

2. WATER RINSE

Between each chemical rinse, a water rinse is necessary to clean the work from any chemical residue.

3. ACID ETCH (Aluminium only)

The surface of the Aluminium is de-oxidised and any contaminants on the surface of the alloy are removed. Etching of the aluminium is vital in preparing the substrate for the oxsilan stage.

4. WATER RINSE

5. DEMINERALISED WATER RINSE

Before entering the tank, the water is passed through a plant that removes all heavy metals and minerals. The water is kept at a conductivity of less than 200 microsiemens. This stage is vital in ensuring the ongoing integrity of the Oxsilan stage.

6. OXSILAN

The substrate is coated by a Silane & Zirconium based polymer. This bonds to the substrate providing the metal with excellent corrosion protection whilst promoting good adhesion.

7. DEMINERALISED WATER RINSE

The water is kept at a conductivity of less than 30 microsiemens. Rinsing the metal completely clean ensures that in the drying stage no contaminants will deposit onto the surface of the metal. Surface impurities could affect the adhesion and the performance of the cured paint finish, Regardless of how good the stages prior to this are, unless the de mineralised rinse is well maintained, the paint will not perform to its full potential.

8. DRYING OVEN

Hot air is circulated around the work to dry the metal off.

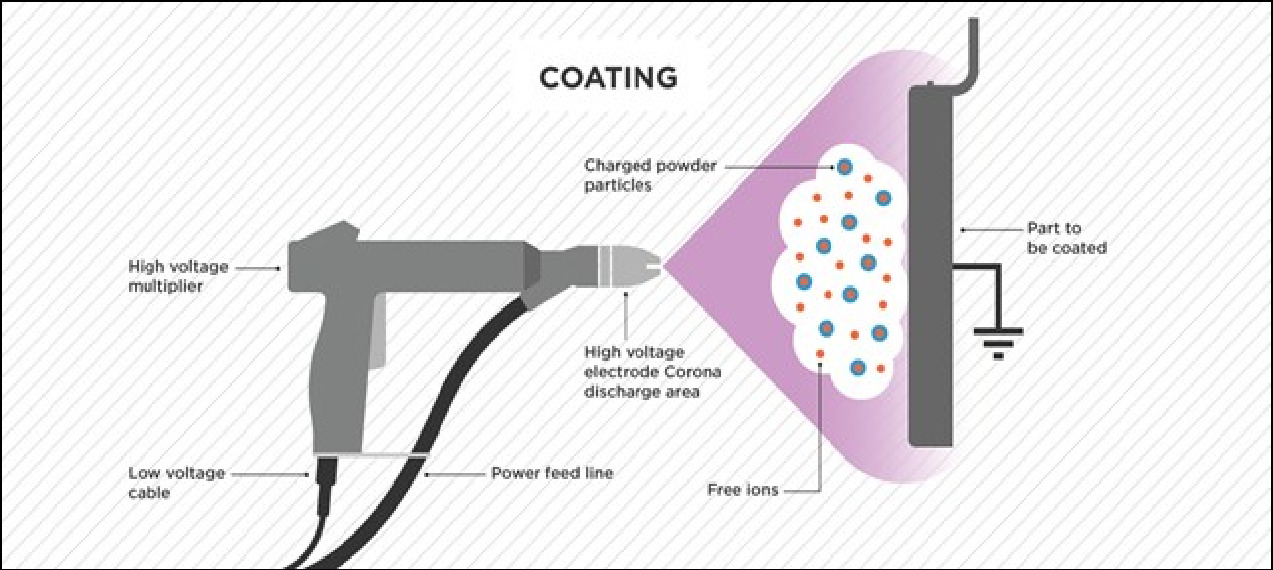

After pre-treatment the metal is suspended on a conveyorised production line and passes into the spray booth for coating. The powder which is held in a fluidised hopper bed is carried to the spray gun using compressed air. As the powder passes out of the gun, the particles are charged and therefore attracted to the earthed piece of metal. This creates an even coating as it wraps around the work piece.

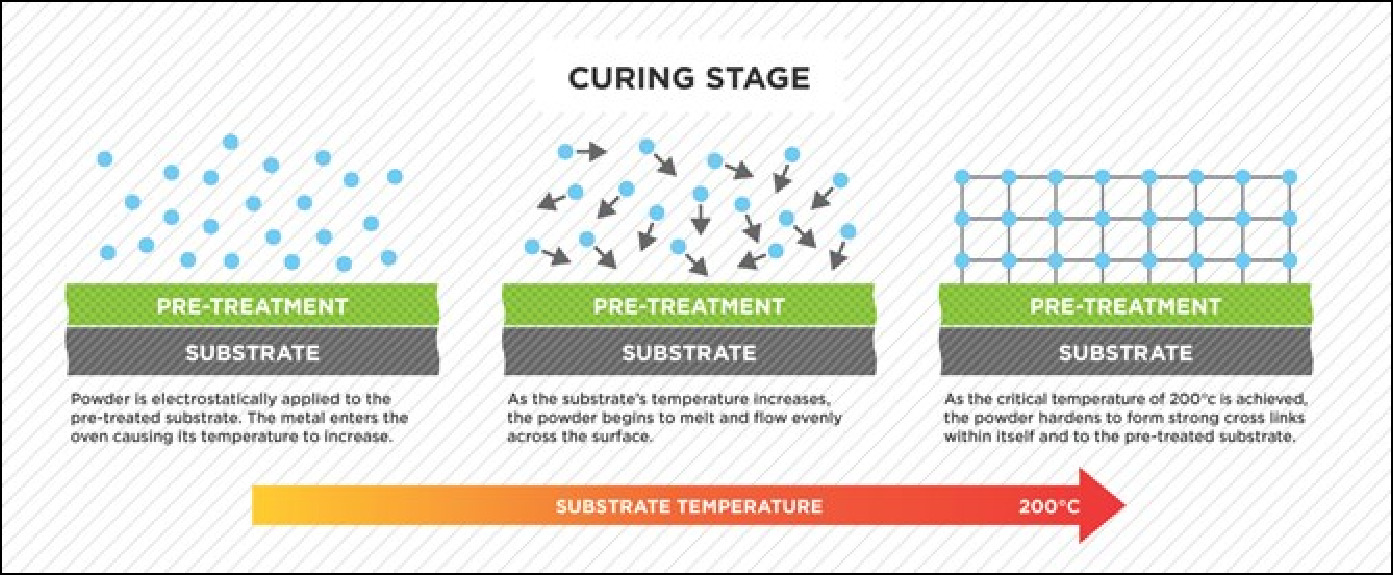

After coating, the production line moves the work into the tunnel oven where it is baked. Once the curing is complete the substrate is inspected for defects, paint thickness, colour and gloss level. Provided there are no issues, the product is packed and made ready for despatch.

Like any manufacturing process, powder coating comes with its own set of potential issues. These range from common defects like orange peel and pinholes to problems with adhesion and coverage. Identifying and rectifying these defects is a key part of ensuring the highest possible quality finish. Understanding the causes and solutions for these issues is critical to preventing rework and rejects.

The environment plays a significant role in the powder coating process. Issues related to humidity, temperature, and airflow can directly impact the quality of the coating. Similarly, contaminants and moisture can also pose challenges. Hence, creating an optimal environment for powder coating is vital to achieving a high-quality finish.

Quality control is an essential part of any manufacturing process, including powder coating. Key tests are performed to assess the quality of the powder coating. These include visual inspection and various measurement techniques. Adhering to industry standards is of utmost importance to ensure the reliability and durability of the coating.

A comprehensive quality control system is key to ensuring consistent, high-quality powder coating. This includes documenting and tracking quality metrics and establishing procedures to maintain high standards. Continual improvement strategies are also employed to enhance the powder coating process and its outcomes.

With rising environmental concerns, the powder coating industry has been moving towards more sustainable practices. This includes the development of eco-friendly powder coating alternatives. These green initiatives are not only good for the planet, but they also have a significant impact on the industry.

The use of powder coating isn't limited to the traditional applications. There are many novel applications being explored, including the development of specialized coatings such as anti-microbial and heat-resistant coatings. These industry-specific solutions are pushing the boundaries of what's possible with powder coating.

Finally, let's address some common questions that people often have about powder coating:

Powder coating and traditional liquid coating are both used to provide a protective and decorative finish to a material, often metal. However, there are significant differences between the two. Powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form, which makes it more environmentally friendly. It's applied electrostatically and then cured under heat, allowing it to flow and form a "skin". This creates a hard finish that is tougher than conventional paint. On the other hand, liquid coating, often called "wet" paint, requires a solvent for the paint particles to mix properly. These solvents, known as Volatile Organic Compounds (VOCs), can be harmful to the environment when they evaporate during drying.

Powder coating is most commonly applied to metal surfaces, including steel and aluminium. However, with advances in technology, it can also be applied to other materials such as plastics and medium-density fibreboard (MDF). The key requirement is that the material should be able to withstand the curing process, which typically involves heating the item to temperatures of 180-200 degrees Celsius.

The length of the powder coating process can vary depending on the size and complexity of the parts being coated, as well as the specific requirements of the job. However, as a general rule, the process could take anywhere from a couple of hours to a full day. This includes the pre-treatment, powder application, and curing stages.

Yes, powder coating is known for its durability and resistance to wear, impact, heat, and UV rays. It provides a long-lasting finish that can maintain its gloss and colour for many years. It also provides superior protection against corrosion, making it an excellent choice for outdoor and harsh environment applications.

While powder coating is generally considered safer than traditional liquid coatings, there are still health and safety considerations to keep in mind. The powder used in the process can be hazardous if inhaled or if it comes into contact with the skin or eyes. Therefore, appropriate personal protective equipment, including respiratory masks and gloves, should be worn during the process. In addition, care should be taken to ensure proper ventilation in the working area to avoid the accumulation of airborne powder.

Whether you're a manufacturer looking to enhance the durability and appearance of your products or a consumer deciding on the best finish for your item, powder coating offers numerous advantages. By mastering the art of powder coating, you can unlock the full potential of this innovative and sustainable coating technology.

As a leading China powder coating manufacturer, Wintoly is dedicated to providing high-quality finishes that enhance the durability, aesthetics, and performance of your products. We have spent years mastering the art of powder coating, allowing us to offer a diverse range of powder coatings tailored to suit various applications. Whether you're seeking a standard solution or custom powder coating services, Wintoly is equipped with the knowledge, experience, and state-of-the-art facilities to meet your specific needs.

The world of powder coating is vast and exciting, filled with numerous possibilities to explore. With advances in technology and an increasing emphasis on sustainable practices, the future of powder coating looks brighter than ever. And as this future unfolds, Wintoly will continue to be at the forefront, innovating, refining, and perfecting our products and processes to offer the best possible powder coating solutions for our customers.

Remember, the secret to producing the best finish isn't just about having the right equipment or following the process correctly. It's also about partnering with a trusted and reliable powder coating manufacturer like Wintoly, who understands the intricacies of the process, the importance of quality, and the value of customization. So, why wait? Unleash the full potential of your products with Wintoly's exceptional powder coating solutions today!

terrychen@wintoly.com

terrychen@wintoly.com

.png) 0086-757-85407388

0086-757-85407388

6 Chaoyang Rd., National Demonstration Eco-industrialzone, Nanhai, Foshan,Guangdong,China

6 Chaoyang Rd., National Demonstration Eco-industrialzone, Nanhai, Foshan,Guangdong,China

.png)