.png)

.png)

.png)

-

.png) 0086-757-85407388

0086-757-85407388 -

-

terrychen@wintoly.com

terrychen@wintoly.com

.png)

.png)

.png)

.png)

When it comes to customizing your motorcycle wheels, the right finish can make all the difference. Whether it's powder coating or painting, both methods offer unique benefits and drawbacks. In this comprehensive guide, we'll dive deep into various factors including cost, durability, and aesthetics to help you make an informed decision.

The coating you choose for your motorcycle wheels isn't just about aesthetic appeal—it's also a crucial decision that impacts the lifespan, performance, and safety of your bike.

When it comes to motorcycle wheels, durability isn't a feature you can afford to skimp on. The right coating, whether it's custom powder coating or traditional paint, plays an indispensable role in protecting against wear and tear, chipping, and corrosion.

While function is paramount, let's not underestimate the value of form. The right coating enhances the overall look of your motorcycle, contributing to its resale value and making it an eye-catcher on the road.

Investing in a high-quality coating may seem costly upfront, but it’s an investment in the long-term health of your motorcycle. A durable coating minimizes the need for frequent replacements and repairs, ultimately saving you money.

Selecting a wheel coating for your motorcycle isn't a one-size-fits-all affair. Your choice hinges on several factors, including your aesthetic preferences, your bike's specific needs, and your long-term maintenance plan. Let's take an exhaustive look at the two main categories of coatings: Organic and Inorganic.

Traditional organic coatings like paint have a long history in automotive finishes. They are crafted from organic polymers and provide a variety of visual effects, from matte to high gloss. However, it’s essential to weigh the pros and cons to determine if this is the right option for you.

1. Color Variety: Paints come in an almost infinite array of colors, allowing for personal customization that can match or contrast with the bike's body.

2. Application Ease: Painting your wheels can often be a DIY project if you’re inclined, saving you on labor costs.

3. Availability: Paints are readily available, and you don’t need specialized equipment for application.

4. Shorter Drying Time: Paints often dry quicker than other coatings, allowing for faster project completion.

1. Durability: Despite their visual appeal, paints are generally not as durable as powder coatings. They are prone to chipping, scratching, and UV damage.

2. Maintenance: Organic coatings often require frequent touch-ups and a protective layer of sealant to maintain their look.

3. Environmental Concerns: Solvent-based paints can be harmful to the environment due to the release of volatile organic compounds (VOCs).

4. Cost Over Time: While initial costs may be lower, the long-term maintenance can add up, making it less cost-effective in the long run.

On the other end of the spectrum are inorganic coatings like powder coating. This modern alternative uses a powder composed of finely ground particles of pigment and resin, which is applied electrostatically and cured under heat. Here’s what you need to know:

1. Exceptional Durability: Powder coating creates a thick, adhesive finish that is incredibly resistant to chipping, scratching, and fading.

2. Environmentally Friendly: Since powder coating doesn't involve harmful solvents, it's generally more eco-friendly.

3. Long-Lasting Finish: The lifespan of a powder-coated finish often outlasts that of a traditional paint job, making it more cost-effective in the long run.

4. Less Maintenance: With a more robust finish, powder-coated wheels usually require less upkeep.

1. Initial Investment: While you may save money in the long run, the upfront cost of powder coating is generally higher.

2. Complexity of Application: Specialized equipment and a controlled environment are essential for applying a powder coating, making it less accessible for at-home DIY projects.

3. Limited Color Mixing: Unlike paint, which can be mixed in numerous shades, powder coating colors are more limited in terms of mixing and layering.

4. Curing Time: The curing process takes longer and involves higher temperatures, requiring a more involved setup.

Painting motorcycle wheels isn't just a cosmetic update; it's an art form meshed with science. From selecting the right paint type to the detailed steps of preparation and application, every decision impacts the quality and longevity of your wheel's new look. Let's delve into this intricate process.

The entire painting process can be broadly categorized into three main phases: Preparation, Actual Painting, and Drying and Curing. Navigating these steps with precision ensures that the end result is both aesthetically pleasing and durable.

The saying goes, "Well begun is half done," and it couldn't be more accurate when it comes to painting. Here are some key preparation steps:

Once the wheels are prepped, it's time to bring out the paint cans. Here are some pointers:

Patience is key in this final step. A rushed drying and curing process can ruin even the most meticulous paint job. Take note of the following:

Painting motorcycle wheels can seem like an inviting DIY project or a quick fix, but it's essential to be aware of the potential downsides. Whether it's about durability or practical challenges, knowing what you might be up against can help you make a well-informed decision.

One of the main issues with painting your motorcycle wheels is the question of durability. While painting may look fresh and vibrant initially, it is more susceptible to chipping, peeling, and scratching compared to more robust alternatives like powder coating.

Even with the most meticulous preparation, there's always a risk of paint running or dripping, especially for those not well-versed in the art of spray painting.

The drying time required between coats and after the final application can often be a significant inconvenience, especially for those who rely heavily on their motorcycles for daily activities.

When it comes to motorcycle customization, powder coating offers a range of benefits over traditional painting methods. From robustness to versatility, powder coating provides a solution that's hard to beat. Let's delve into what the powder coating process entails.

Read More: Powder Coating vs. Paint: Unveiling the Pros and Cons

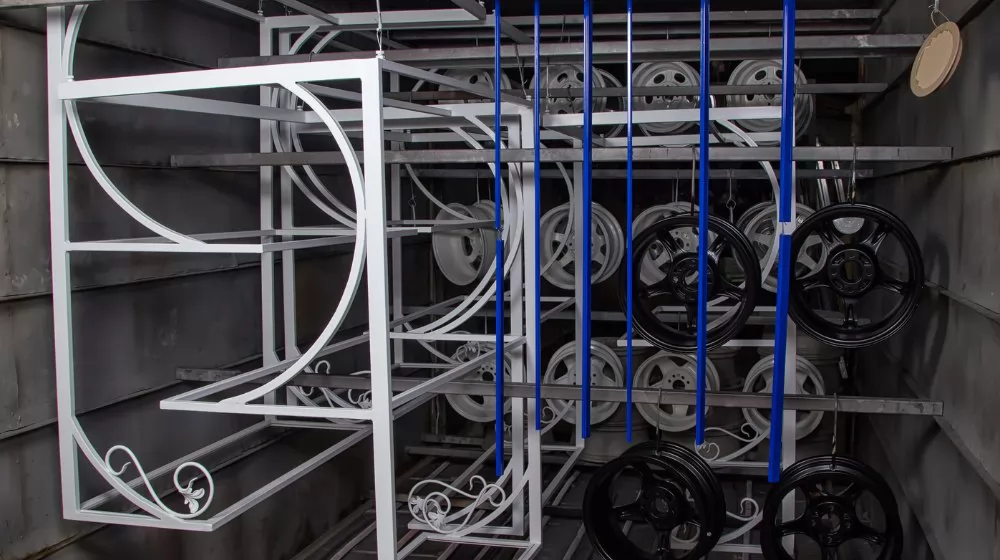

The process of powder coating your motorcycle wheels involves a series of steps aimed at producing a durable and high-quality finish. Unlike traditional paint, powder coating uses a dry powder applied electrostatically, which is then cured under heat to form a hard layer.

The first step is to adequately prepare the wheel surface. All old paint, dirt, and rust need to be removed to ensure proper adhesion of the powder. Sandblasting is a common method for achieving this. A clean, bare metal surface is ideal for powder coating.

The next step is the application of the powder. The powder is loaded into a special spray gun designed for this purpose. Using the gun, an electrostatic charge is applied to the powder particles, causing them to stick to the grounded metal surface of the motorcycle wheel. It's crucial to ensure even coverage for a consistent finish.

After the powder has been applied, the wheels are placed into an oven where they're heated to temperatures ranging from 375 to 400 degrees Fahrenheit. This process melts the powder, which then flows and fuses into a hard, protective coating. The curing time usually varies between 20 and 30 minutes.

When it comes to powder coatings, there are two main categories: Thermosets and Thermoplastics. Both have their pros and cons, and the best choice depends on your specific needs, the environment in which the motorcycle operates, and aesthetic preferences.

Thermoset powder coatings are the most commonly used types of powder coatings and are known for their durability and resistance against high temperatures and chemicals. When cured, thermosets undergo a chemical cross-linking process, which makes them highly resilient.

Thermoplastic powder coatings, on the other hand, do not undergo any chemical change during the curing process. This makes them more flexible but somewhat less resistant to chemicals and high temperatures compared to thermosets.

Powder coating has been gaining traction for a reason. When it comes to advantages, powder coating holds several cards up its sleeve, making it a fantastic choice for motorcycle enthusiasts. Let's examine some of these benefits.

Powder coatings offer remarkable durability compared to conventional paint. Thanks to the electrostatic application and thermal curing process, it creates a hard, resilient surface that can withstand various environmental elements like UV rays, moisture, and chemicals.

One of the biggest nightmares when painting is the risk of runs, drips, or sags. Powder coating eliminates this concern. The electrostatic application ensures an even layer of coating, giving your wheels a professional, smooth finish.

Unlike traditional paints that can take hours or even days to fully dry, the curing time for powder coating is considerably less, often around 20 to 30 minutes in the oven. This means your wheels are ready for action sooner.

The debate between powder coating and painting is a long-standing one in the world of motorcycle customization. Both methods come with their own sets of advantages and drawbacks. Let's break it down across several parameters.

On the surface, painting your motorcycle wheels can seem more budget-friendly. The initial outlay for paint and supplies is generally lower. However, when we factor in durability and maintenance, powder coating often becomes more cost-effective in the long run.

Powder coating takes the lead in terms of durability. The electrostatic application and curing process create a hardened, uniform layer that stands up better to environmental challenges like moisture, chemicals, and UV rays. Paint, on the other hand, tends to fade quicker and is less resistant to chipping and scratching.

As mentioned earlier, powder coating excels in withstanding harsh environmental conditions. Whether it's UV exposure, salt, or chemicals, powder coating usually stands strong. Traditional paint coatings are more susceptible to these elements, requiring more frequent maintenance.

Powder coatings are known for their excellent resistance to scratching and chipping, thanks to their chemical composition and curing process. Paints are generally softer and more vulnerable to such damages, especially if a good quality primer and topcoat are not used.

Both powder coating and painting offer a wide array of colors and finishes. While powder coating used to lag in this department, advancements in technology have broadened the spectrum of available colors and textures.

Paint allows for intricate detailing and custom designs more easily than powder coating. However, powder coating is catching up in this aspect as well, with new techniques allowing for multi-layer applications and custom finishes.

Painting requires multiple layers and often needs sanding between coats, making it a more time-consuming process. Powder coating is generally quicker as it requires fewer coats and no drying time between applications.

Powder coating is a winner in this category as well. Once the powder is applied, it only requires about 20 to 30 minutes of curing in the oven. Paint, conversely, can take hours or even days to dry fully.

Both methods can be either DIY or professionally done, but painting is generally more accessible for the average person. Powder coating requires specialized equipment like electrostatic guns and curing ovens, which may not be practical for home use.

Painting needs basic tools like paint, brushes or spray cans, and sandpaper. Powder coating, however, demands a more specialized toolkit that includes an electrostatic spray gun, an air compressor, and a curing oven.

While neither method is particularly hard to master, powder coating has a steeper learning curve due to its specialized equipment and techniques. Painting is generally easier to get into and allows for more room for error.

Now that you've gone through this exhaustive comparison, the superiority of powder coating in terms of durability and finish might be quite evident. If you're leaning towards powder coating for your motorcycle wheels, we highly recommend Wintoly, a leading powder coating manufacturer and custom powder coating solutions provider. With years of expertise and a variety of color options, we bring your vision to life.

To explore our state-of-the-art powder coating options, visit www.wintoly-coatings.com and kickstart your next project with confidence.

Read More:

1. What is powder coating?

2. What are the benefits of using powder coating?

3. What industries commonly utilize powder coating?

4. How do I choose a reliable powder coating supplier?

5. What types of powder coatings are available?

6. What is the typical minimum order quantity (MOQ) for powder coatings?

7. Can I request custom colors or formulations?

8. How do I ensure quality control when ordering powder coatings?

9. What are the typical curing requirements for powder coatings?

10. What are the payment terms typically offered by powder coating suppliers?

11. How can I request samples of powder coatings?

12. What should I consider when applying powder coatings?

When selecting a powder coating supplier, it’s essential to evaluate their product offerings, quality assurance processes, and customer service. Doing thorough research can help you find a supplier that meets your specific needs effectively.

terrychen@wintoly.com

terrychen@wintoly.com

.png) 0086-757-85407388

0086-757-85407388

6 Chaoyang Rd., National Demonstration Eco-industrialzone, Nanhai, Foshan,Guangdong,China

6 Chaoyang Rd., National Demonstration Eco-industrialzone, Nanhai, Foshan,Guangdong,China

.png)